Alex Gudilko, CEO of AJProTech - IoT Product Development Studio in Los Angeles, California.

Creating hard tech is no walk in the park. The process is complex, the costs are high and the challenges are plentiful. But despite all that, it's still worth pursuing. In this article, we'll take a deep dive into the world of hardware development for the Internet of Things (IoT), shedding light on the common pitfalls and the importance of being well-prepared and optimistic. Pcb Production Line

What are the common challenges for physical products?

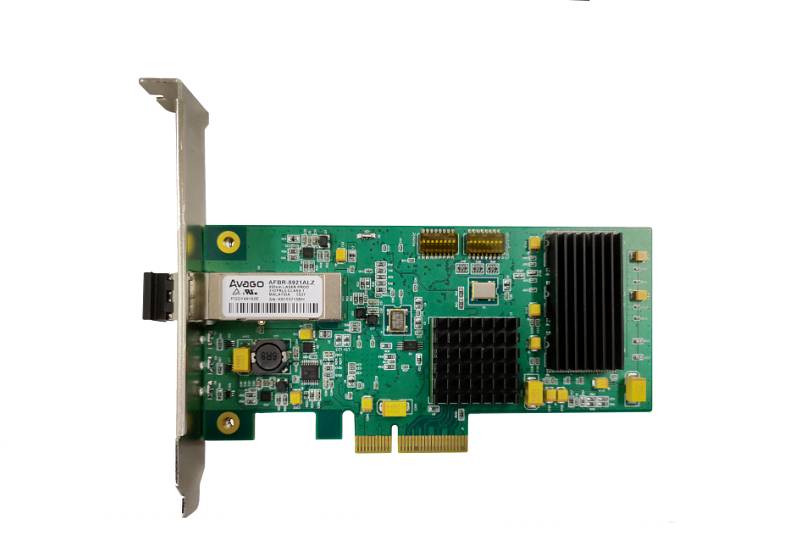

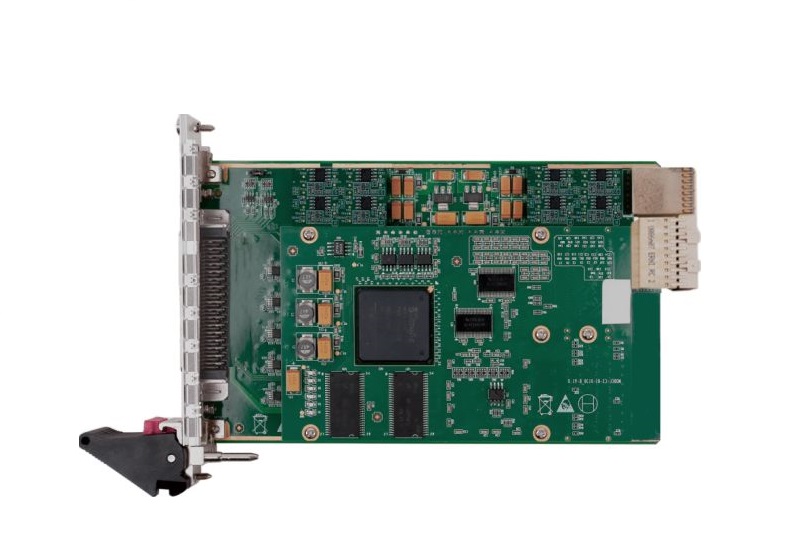

High cost: Hardware products are predictably more expensive to develop and manufacture than software. They require physical components—circuit boards, sensors and actuators.

Long development time: It may take years to bring hardware to market since development often involves multiple iterations of design and testing.

High risk of failure: The failure rate for hardware startups is high due to many factors such as design flaws, manufacturing defects and market changes.

Despite the challenges, there are many rewards to building hardware products:

Large Potential Market: The market for hardware products is large and growing, especially due to increased demand for domestically manufactured high-tech products.

Long-term Cost Savings: Custom hardware products may involve higher upfront costs than off-the-shelf solutions but may be beneficial long term. Custom devices require less maintenance and eliminate ongoing licensing fees.

Brand Recognition Is Stronger: Physical products have the advantage of placing you ahead of your competition and promoting brand recognition. In simpler terms, physical experiences create a stronger emotional bond with your clients.

Start from initial research—how do people solve this problem now and how much does it cost? Consider doing early customer research with surveys. Don't pitch them a new idea, but simply ask what tools they use, how much they pay and what challenges they have. The problem comes first and the solution comes second.

It might take a while before you can raise funds or generate sales. In the early days, most founders use their own money to pay for prototypes or go through FFF round (Friends, Family and Fools)—usually $30,000-$100,000. Be lean—your team should only include essential people who can directly contribute to product development. The critical skill required at this stage is to get things to work. FAST.

You must produce your Minimum Viable Product (MVP) as soon as possible. A famous joke—if you like your MVP, you spent too much time on it. Create an MVP in 1-3 months and start collecting early feedback. It does not need to be pretty and have all the features. It just needs to show the core function. Be ready to pivot; nothing is set in stone at this stage.

Your MVP works and you're ready to scale but you may be running out of funds. How to finance your team, office space, marketing activities and even inventory? Yes, you need to raise funds again. What options do you have?

Crowdfunding is taking pre-orders for products before they are manufactured. Quite a few success stories appeared on Kickstarter and Indiegogo (MATE or Pebble). But the game has changed. Crowdfunding became a "Pay to Play" game; you need to invest in marketing first. Between prototypes, videos, email lists and ads, expect to spend $20,000-$100,000.

Don't rush into crowdfunding too early. Do proper research on technical challenges, evaluate production costs and get a realistic timeline. When we develop new products, we start with a Feasibility Study first:—to know how it works, looks and costs.

You must be certain you can meet your funding goal. Campaigns that fail to meet their target will have a hard time raising funds from investors.

For your first product, angel investors are your best friends. Besides financial support, they will provide industry expertise and networking opportunities. Evaluate targeted markets where your product can potentially thrive in, and find angels in a particular field. Investors are not quick to endorse untested concepts; they demand demonstrations of technical prowess and a thorough Feasibility Study.

Having received funding, what should you do next? Hire engineers who are skilled in designing products specifically for manufacturing purposes. With the aim of ensuring a high-quality end product, go through 2-3 iterations of product development and validation. Each iteration takes approximately 3-6 months to complete. The costs can vary depending on the complexity and scale of the product, ranging from $100 000 to $1M.

Choosing the right Contract Manufacturer (CM) is a critical decision that can greatly impact the success of your venture. Ask yourself what are the non-negotiable requirements first (cost, geography, experience). Start search on websites like Alibaba and find at least 10-20 CMs. Narrow your list to a Top 5, evaluating their location, track record and reputation. Sign Non-Disclosure agreements (NDA) and get quotes from them all. Pick 2-3 winners who have experience with similar products and provide competitive offers. Never select solely on price and always have a Plan B.

Working with overseas manufacturers is a tiring process. You may consider partnering with a Product Development engineering team experienced working with international manufacturers. For more insights on cost-effective manufacturing of consumer electronics, read "Manufacturing Consumer Electronics Without Breaking the Bank."

How to set a price for your product? The traditional rule of thumb is that your Cost to Make should not be more than 20%-25% of your retail cost. Many companies explore selling hardware at cost and making money on software (e.g., Kindle, Oculus). Whatever you choose, avoid double dipping—selling full-price hardware and mandatory subscriptions may decrease customer loyalty. A subscription is an option, reducing your margin in the cost of hardware.

The final stage of the electronics development process has brought you to this pivotal moment, where meticulous planning and strategic considerations come together to push your creation into the hands of eager consumers. With final touches, prepare to disrupt, revolutionize and make a lasting impact in technology. This is just the beginning of an extraordinary journey.

Forbes Technology Council is an invitation-only community for world-class CIOs, CTOs and technology executives. Do I qualify?

I am a New York-based summer wealth reporter at Forbes. I am a recent graduate of the Columbia Graduate School of Journalism, prior to which, I worked and studied in Ireland, covering European finance and economics. I am originally from Boston, Massachusetts.

I am a New York-based summer wealth reporter at Forbes. I am a recent graduate of the Columbia Graduate School of Journalism, prior to which, I worked and studied in Ireland, covering European finance and economics. I am originally from Boston, Massachusetts.

Successful CIOs, CTOs & executives from Forbes Technology Council offer firsthand insights on tech & business.

Darren is president of Uniform DXCP, which helps businesses deliver omnichannel, modern experiences with the best-of-need technologies. Read Darren Guarnaccia's full executive profile here.

Group Head of Data and AI at Team Internet Group PLC. Read Pawel Rzeszucinski's full executive profile here.

PCB design Roman Vrublivskyi is the experienced CEO of SmartHub, a global ad tech company that provides white-label programmatic solutions. Read Roman Vrublivskyi's full executive profile here.